New self-retracting needle can cut rate of failed intravenous injections

5 September 2011

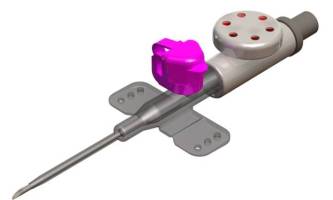

A new form of needle with an automatic mechanism to reduce the rate of failed intravenous injections has been co-developed at Nottingham Trent University and Oberon Medical Innovations.

The University's School of Architecture, Design and the Built Environment has been working with Olberon Medical Innovations to create a self-retracting needle, which addresses the common problem of passing completely through a vein.

It is estimated that there are up to 25 million intravenous injections, or cannulations, in the UK each year, with up to a third expected to fail first time. A major problem with current needles is that operators find it difficult to detect when they have successfully located and punctured the vein, causing the needle to pass through the other side and fail in its positioning.

The new needle has an automatic mechanism which, based on changes in pressure, causes it to withdraw the moment it detects the move from tissue to vein. The product — Advanced Intravenous Cannula for Improved Insertion Success Rate — is patent protected and the researchers are working with medical suppliers to develop a partnership for its mass manufacture.

A design-drawing of the new self-retracting

needle

Researchers say the needle, which builds on existing designs but with a number of additional components, can be made at a comparable price, while providing better value for money, saving time and reducing the suffering of patients. The research came about due to a long term collaboration between the University and Olberon Medical Innovations — based at the University of Nottingham — which aimed to identify common medical problems that could be solved through design.

It has been funded via an Innovation Fellowship grant given by the East Midlands Development Agency and the European Regional Development Fund. Researcher Dr Amin Al-Habaibeh, an expert in advanced design and manufacturing technologies in Nottingham Trent University's School of Architecture, Design and the Built Environment, said: "This is a simple but innovative concept which we feel provides an ideal solution to the common problem of failed intravenous injections. When the needle hits the vein the pressure moves a diaphragm which activates its withdrawal by the force of a tiny spring.

"The new needle is used in exactly the same way as existing products, but, essentially, it works automatically. This means we no longer need to rely on the operator alone and their understanding of when a vein has been punctured."

Dr Arash Bakhtyari, the managing director of Olberon Medical Innovations, said: "This advanced intravenous cannula represents a significant improvement on existing products by making the detection of vessel entry and withdrawal of the inner needle automatic. Intravenous injection is the world’s most common invasive medical procedure, and 80% of patients admitted to UK hospitals will receive a cannulation.

"This invention highlights the importance of the industry working with academia, which in this case has provided a unique and novel medical invention which is expected to help patients and the doctors across the globe."