Open Bionics 3D printed prosthetic hand reaches global finals of Intel competition

11 September 2014

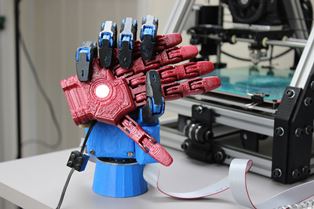

Robotics startup Open Bionics has seen its idea to significantly reduce the cost of prosthetic limbs by using 3D printing reach the global final of Intel's Make it Wearable Competition.

Joel Gibbard and Sammy Payne of Open Bionics, which is based in the incubator at the Bristol Robotics Laboratory (BRL), submitted a video explaining their idea for a robotic prosthetic hand that will cost less than £600 to make.

As finalists the team has already won $50k and will soon enjoy an opportunity to fly to the United States for mentoring and training as one of ten projects that will compete to win the competition’s $500k first prize.

Open Bionics’ prosthetic hand offers much of the functionality of a human hand. It uses electric motors instead of muscles and steel cables instead of tendons. 3D printed plastic parts work like bones and a rubber coating acts as the skin. All of these parts are controlled by electronics to give it a natural movement that can handle all sorts of different objects.

The Dextrus robotic hand. Image credit: Joel

Gibbard

Joel Gibbard said, “Aside from the initial cash prize, which will provide invaluable funding for our project development, this is a great opportunity for us to learn about product design and business from experts at the incubation programme at UC Berkeley in the US.”

“Open Bionics is open-source, which means that all of the know-how needed to create a robotic prosthetic hand will eventually be posted on our website. The idea is that potentially anyone can improve and customise the designs themselves, and then upload them for everyone to share.”

Joel continued, “We've made some great progress in the last few weeks. We've got the circuit boards working and controlling the motors, all that needs to be done now is a few more tweaks on the hand design and for the code to be written. I've enlisted the help of an embedded software developer that I work with at the BRL so we'll be working on this over the next few weeks. The aim is to send out our prototype hand before the end of the Make It Wearable competition and receive some useful feedback on its performance.”

Joel is also currently working on a mini robot hand designed to work on small humanoid robots using a new flexible material that is 3D printed in one piece and requires very little assembly.

Further information

The OpenBionics website: www.openbionics.com

MAKE IT WEARABLE is a global year-long initiative sponsored by Intel to support the evolution of wearables. Wearables are devices, clothing and accessories that are attached or worn on the body and incorporate or are enhanced by computers and advanced electronic technologies. The next wave of smart, connected wearable products and services may share the vision of interweaving technology into everyday life, offering enhanced user experience. So far clothing, stickers, medical devices, temporary tattoos and accessories like watches, glasses, wristbands and more are on the market or in development. https://makeit.intel.com/

Bristol Robotics Laboratory is the leading and largest academic centre for multi-disciplinary robotics research in the UK. It is a collaborative partnership between the University of the West of England (UWE, Bristol) and the University of Bristol. The Technology Business Incubator at the Bristol Robotics Laboratory (BRL) is a unique pilot program to stimulate and support technology start-ups. It includes undergraduate, graduate, post-graduates, staff and partner spinout businesses to ensure up-to-date and detailed understanding of technology start-up needs and enhance BRL's creative and entrepreneurial culture. It also provides valuable input into taught courses, research and research exploitation. www.brl.ac.uk